Measurement

Air Gaging Transforms Manufacturing Processes in Automotive and Aerospace Industries

These devices find extensive use in various manufacturing processes, from automotive to aerospace industries.

All Images Source: Fowler

Air gage measuring devices play a crucial role in ensuring precision and quality control in the manufacturing industry. These instruments utilize air pressure as a means of measurement, offering a reliable and accurate way to assess the dimensions and tolerances of machined components.

One of the key advantages of air gaging is its non-contact nature, making it ideal for delicate or easily deformable materials. The basic principle involves directing a controlled stream of air through a nozzle onto the part being measured. The resulting back-pressure or resistance is then measured and correlated with the part’s dimensions.

These devices find extensive use in various manufacturing processes, from automotive to aerospace industries, where tight tolerances and high-quality standards are paramount. Air gages are particularly valuable for applications where traditional contact-based measurement tools might be impractical or risk damaging the components.

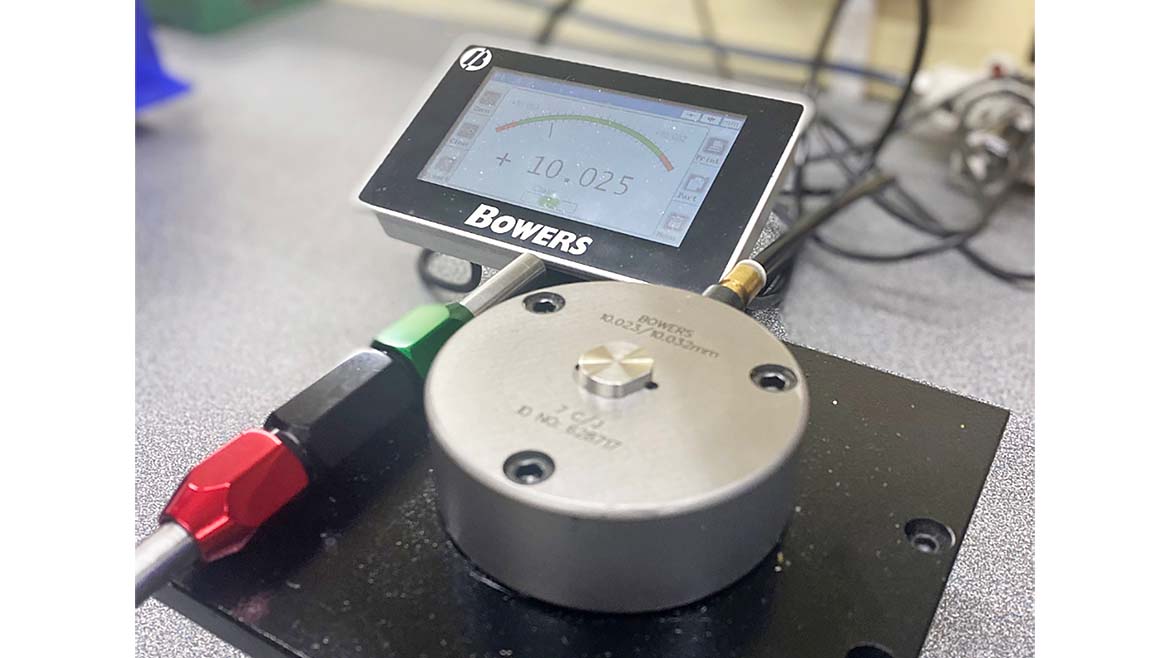

Advancements in technology have led to the development of sophisticated air gage systems that offer enhanced accuracy and automation. Modern air gages often integrate electronic components for precise data acquisition and real-time monitoring. Some systems even incorporate computerized controls to streamline the measurement process and provide immediate feedback to operators.

In terms of types, air gages come in various forms, including plug gages, ring gages, and snap gages, each designed for specific measurement tasks. Plug gages, for instance, are used to measure the internal dimensions of holes, while ring gages are employed for external diameter measurements. Snap gages are versatile tools that can measure both internal and external dimensions, making them suitable for a range of applications.

Measurement

More on Air Gaging

The benefits of air gaging extend beyond accuracy and non-contact measurement. These devices are also known for their speed, allowing for rapid assessment of components in high-volume production environments. The quick and reliable feedback provided by air gage systems contributes to efficient manufacturing processes, reducing cycle times and enhancing overall productivity.

Moreover, air gages are well-suited for measuring complex geometries, such as irregular shapes or parts with multiple features. Their adaptability makes them indispensable in industries where components vary significantly in design and size.

As manufacturing technologies continue to evolve, so do air gage systems. Some of the latest advancements include the integration of artificial intelligence (AI) and machine learning algorithms into air gage setups. These smart systems can learn from historical data, adapt to variations in production, and optimize measurement processes for increased efficiency.

In conclusion, air gage measuring devices have become indispensable tools in the realm of manufacturing quality control. Their non-contact nature, speed, adaptability, and evolving technological enhancements make them crucial for ensuring precise measurements and maintaining high-quality standards across diverse industries. As manufacturing processes advance, it’s likely that air gage systems will continue to play a pivotal role in meeting the ever-growing demands for accuracy and efficiency in production.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!