ASNT Column | Eddie C. Pompa

Space Waste … but not what you’re thinking

Source: Getty Images/iStockphoto

As an inspector at the Johnson Space Center (JSC) there are opportunities to perform inspections on unique and one-of-a-kind products that make one feel special and proud to be part of such a great team. Among these items there are many you would expect and others we take for granted that include pressure vessel inspections, ground support equipment, and infrastructure fabrication. The more interesting test items include things like Space Shuttle Tiles, impact samples, research & development hardware, and astronaut equipment.

Inspecting astronaut equipment is where it gets interesting as it brings so much variety and uniqueness to what might be a normal nondestructive testing (NDT) job. We were told that we would be receiving a piece of hardware from the International Space Station (ISS) as soon as the current Space Shuttle landed and that we would need to use extra caution. Normally extra caution comes standard with the job but it did not prepare for the package I received later that week. The packaging was not what I expected as the most notable difference was the “Biohazard” label on the outside of the crate. With no rush to open this box I waited for the project engineer to stop by and provide more details about this package and what exactly they needed me to do with it.

It turns out the package inside was part of the ISS Waste Disposal System (ISSWDS) as NASA likes to use acronyms every chance they get. This device was a cartridge similar in size to those you see at banks to transport items to and from the customer in the drive through lane. The contents of these cylinders were “human feces” separated by individual pouches similar to the “Diaper Genie” except compacted as one might expect where storage space is a premium. The extra caution now appeared obvious and brought about immediate displeasure with the job ahead.

NDT

A Quality Special Section

The job “should we choose to accept it” was to X-ray the containers in both the 0° and 90° directions using our digital panel for engineers to evaluate the content for proper compaction. The purpose for using the digital X-ray system had two strong advantages that appealed to all parties and most important was the exposure time. With digital radiographic panels exposure times are cut dramatically which was of extra importance to me as I did not want these in my possession any longer than I needed to. In the case of the engineer, they wanted the latitude that came with digital radiography. Digital radiography uses a semiconductor-based sensor panel to convert X-ray energy into electrical signals which eliminates the middle step of creating a latent image. The latitude of the image results is a byproduct of the ability to enhance or adjust contrast, sharpness, and brightness to enhance areas of interest among various material densities.

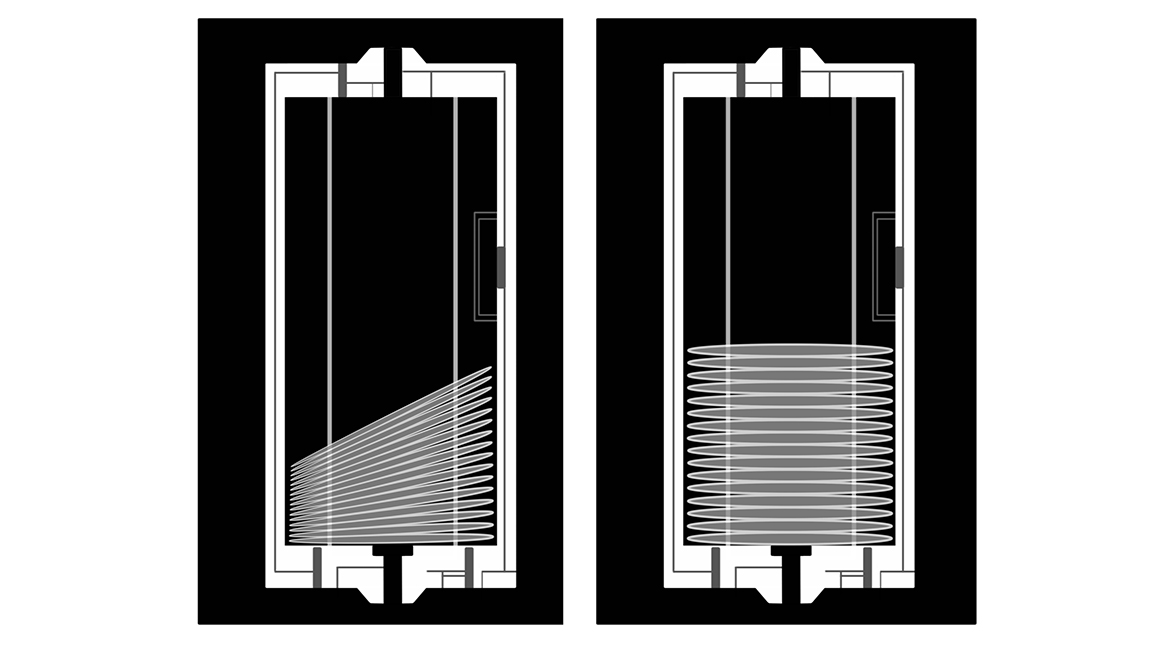

The objective was to determine the quality of compaction of the waste. The ideal compaction was to have each disk equally compressed and parallel with each other through the entire volume of the cylinder. It turns out that many of them were not and nearly 45° off which didn’t look good to engineering. It did not look good to me either as handling someone else’s waste was not what I had planned to do for work that day. Luckily for me there was no leakage of fluids and I managed to give them the images they needed to make their decision on what to do next. I never heard back from the project team so I suspect they were able to get things corrected and I was on to my next radiographic inspection.

The following are artistic representations to illustrate the ideal and actual radiographic results taken from the International Space Station.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!