NDT | Computed Tomography

How Nondestructive Testing is Driving Sustainable Quality in the Automotive Sector

NDT techniques are available that are just as quick as destructive methods but also offer a more sustainable use of raw materials.

A casting part is being scanned in a gantry CT system from Waygate Technologies. Image source: © Waygate Technologies, ZSW/Waygate Technologies

The automotive industry is one of the most dynamic industrial sectors worldwide. It manufactures more than 70 million vehicles of ever-increasing technical complexity each year. The sector develops and applies technologies that set the standard for other industries. The global contribution of this industry to the world economy is approximately $3.4 trillion (2021 – Mc Kinsey). Yet very little is communicated about the nondestructive testing (NDT) techniques used for industrial inspection to meet those often mutually opposed pressures of productivity and quality.

In recent years, the automotive industry has been faced with the challenge of accommodating radical and ever more rapid change on multiple levels. Global mobility trends and rigorous regulations of emissions and fuel consumption are forcing automotive manufacturers to heavily invest in new drive systems like full electrical and hydrogen drive trains or optimizing conventional engines. The preferences of drivers on the other hand dictate the fast-paced development of advanced features that enhance driving comfort, like connectivity and increasingly autonomous assistance systems. Shouldering these large investments inevitably increases the cost pressure for OEMs. Digitalizing the development and manufacturing processes can boost production efficiency and reduce costs but also entails more new technologies and methods. Throughout these rapid changes in the automotive manufacturing environment, OEMs and suppliers need to safeguard the quality of all parts.

In addition, the auto industry is of course also subject to the same ramifications of sustainability efforts that affect all manufacturing environments. Conserving resources and reducing scrap and waste will be an integral part of the life cycle of any product in the future. This is also something that modern industrial inspection methods and technologies can support.

DESTRUCTIVE QUALITY MANAGEMENT

In the early days of the automotive industry, formalized quality control was quite basic. Mass production was based upon the concept of process repeatability and that repeatability creates consistency, which in turn means controlled quality. Naturally, there were random checks to ensure that production line operations were being carried out satisfactorily and these checks mostly involved the destructive examination of a component. Destructive testing was not exclusively applied, however. In the quality control regimes of many suppliers, for example, X-ray has been used extensively for decades in the inspection of castings and engine blocks.

Nonetheless, the employment of destructive examination practices is still very much in evidence in the production environment, even today. This is mainly because they are embedded in the manufacturing culture but also because destructive techniques offer a very fast solution to inspection. Unfortunately, they also create a great deal of scrap, and a lot of re-working is involved, so that considerable costs ensue.

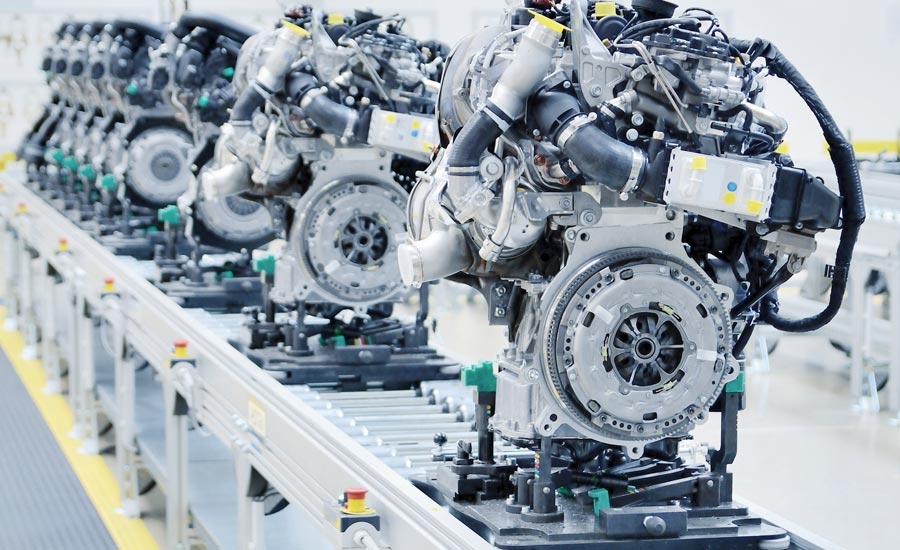

Line of chassis in automotive manufacturing plant Image source: © Waygate Technologies, ZSW/Waygate Technologies

NONDESTRUCTIVE QUALITY MANAGEMENT

Fortunately, nowadays also nondestructive testing (NDT) techniques are available that are just as quick as destructive methods but also offer a more sustainable use of raw materials, while providing more comprehensive and more reliable inspection. Most methods are digital, so the integration of data streams into a current process flow is a common task.

The first and easiest aspect of any nondestructive inspection however is to look at the designated part. Visual inspection is thus an integral component of most inspection procedures. In case the part cannot be accessed directly, video probes are used. In manufacturing environments, this will largely be for final checks to guarantee that parts and their assembly meet quality standards, correct measurements and are impermeable to water, for example. Many components and parts like engines will also be inspected this way during the engineering and development phases.

Radioscopic (X-ray tube and digital detectors) examination is carried out on engine blocks, wheels, and other safety relevant components. The quality of these examinations continues to improve as X-ray tube technology and digital image processing continue to evolve. Where conventional radiography (2D) was performed, this is now increasingly replaced by digital radiographic computed tomography (CT).

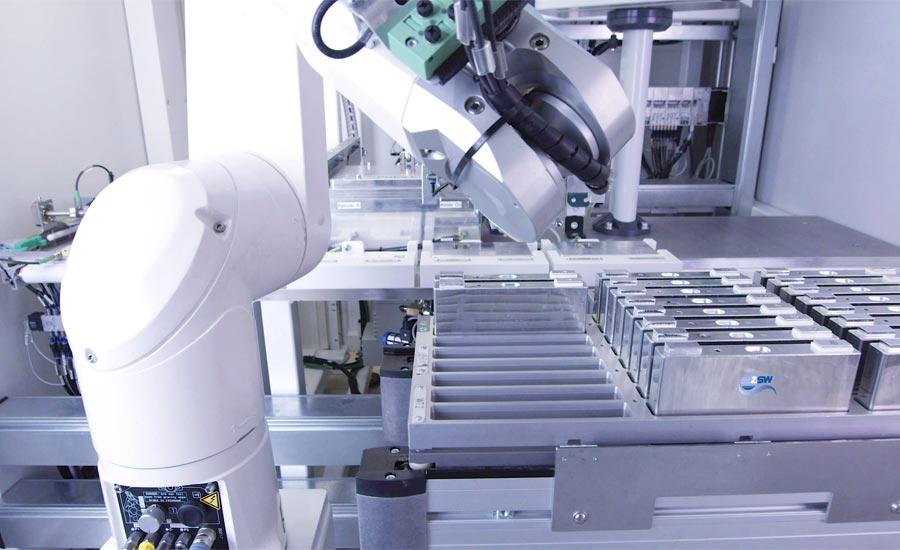

Assembly of PHEV-1 cells at ZSW in Ulm, Germany Image source: © Waygate Technologies, ZSW/Waygate Technologies

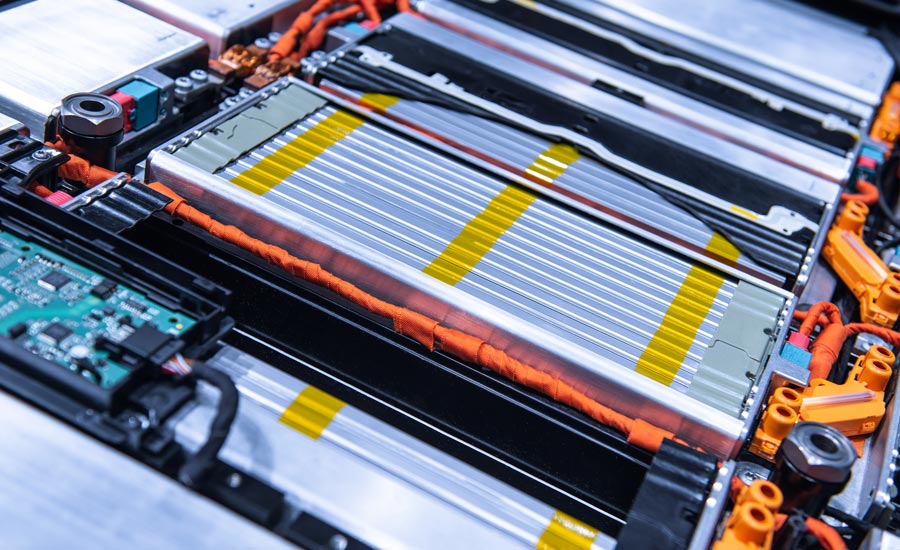

CT has been used for automotive applications for more than 20 years. In the early days, more basic CT systems that were based on systems for the medical sector were transferred to industrial laboratory environments to perform specific inspections. With the advancement of the technology, the role of CT in automotive inspections has however grown significantly. A number of hardware and software developments for example today facilitate the use of CT within a production environment and even within assembly lines. Inline-CT inspection means that scans of battery cells can automatically be performed within the production line. This relatively new development was predominantly facilitated by software innovations like assisted and automatic defect recognition (ADR). The field of ADR still holds large untapped potential to increase productivity, especially in combination with deploying artificial intelligence (AI). A current aim would be a fully automated production line including quality control systems that automatically sort out corrupted parts and provide insights on the cause of defects as well as on the stability of the process itself.

Eddy current inspection is another technique that has been adopted by the industry and is used on a variety of components, such as master cylinders, bearing races and pistons, for crack detection and hardness testing. Modern eddy current systems feature a high sample frequency to allow inspection at very fast line speeds and delayed alarm output signals are used to control down-line marking units or accept/reject gates.

Similarly, ultrasonic equipment and systems are increasingly specified to provide integrity testing. Ultrasonics has long been a preferred technology for weld inspection in many industries and manual ultrasonics is fast replacing destructive testing, for example in the testing of spot welds.

Gearbox assembly in automotive manufacturing plant Image source: © Waygate Technologies, ZSW/Waygate Technologies

THE EVOLUTION OF NDT FOR AUTOMOTIVE

However, escalating cost pressures and the use of new materials in the automotive industry are doing much to facilitate and accelerate the deployment of NDT methods and technology. The use of new and different materials requires new and different joining techniques, such as laser welding and adhesive bonding, where inspection solutions already exist. It is important that these new inspection solutions can be integrated into the production line (i.e. inline inspection with ADR). To help OEMs and suppliers meet their sustainability targets, it is also necessary that NDT solutions improve productivity as well as reduce scrap and rework costs. Automated inspection is now feasible for a lot of inspection tasks and has the added advantage that feedback inspection results can be used to positively affect control over the relevant process.

EV battery packs Image source: © Waygate Technologies, ZSW/Waygate Technologies

All of the modalities used in NDT today provide an easy-to-understand display and reporting of inspection results. Naturally, this means that an enormous amount of data is generated. Fortunately, the necessary software like ADR, data management and interfacing, data archiving, and remote monitoring and diagnostics is readily available to manage, analyze and store this data. It is even possible to compare and analyze data from different modalities, even from destructive examinations if those are still conducted.

These developments, both in technology and in attitude, are to be welcomed by automotive manufacturers and their suppliers alike. Innovative inspection solutions will help drive down costs by reducing scrap and reworking efforts. They will help shorten prototype development times by providing accurate and reliable information of manufactured prototype designs. They will minimize the cost of product recalls, both in financial terms and in terms of damage to a company’s image. The most intelligent NDT inspection solutions in the market will help automotive manufacturers and suppliers achieve their goal of producing the required number of highest quality products in the most cost-effective manner.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!