Assessment of a Best Practice

The goal is to achieve excellent results.

In management literature you will often encounter the concept of a best practice. However, until recently no method was available to assess a best practice.

Why do we need a method for a best practice assessment?

Proof of need: when you search for “best practice” in Google, you get more than 1.76 billion hits. If you analyze a small number (100), you will discover that only a very few are true best practices. Why is this? No best practice writer had a tool until now to assess whether they really had a best practice. They can now make an accurate assessment for the first time, using the BEST-tool.

If a leader could use a tool to discover how good their approaches and methods are, and how excellent their achieved results are, they could plan further improvements. The goal is to achieve excellent results.

BEST is an acronym and means “a Better way to Excellent results and Success through the application of an appropriate Tool.”

Many managers want to know and measure how good their enablers, results, and processes are without doing a lengthy and difficult research for a good benchmarking company or organization. By applying the BEST-tools, they not only know whether they have a best practice, but they see to what extent it is a best practice and where they need to take action for improvement.

An enabler provides a means, method, or opportunity. (https://www.merriam-webster.com/dictionary/enable) For a process to be a best practice, it must enable an organization to execute its strategy more efficiently and effectively, aligning the company more closely with its objectives. (www.mckinsey.com). The lean management enterprise, A system for daily progress, meaningful purpose, and lasting value. January 2014)

Our definition of a best practice:

A best practice is a process which is regularly reviewed and improved, monitored by key performance indicators, and incorporating lessons learned. A best practice contributes to the concretization of the strategy of the organization and leads to excellent and sustainable results.

There are some additional attributes of a best practice:

- It produces consistent, measurable, reliable, and excellent organizational results.

- It improves the organization’s performance.

- It leverages and takes advantage of technology and innovation.

- It improves quality and speed, thereby lowering costs.

- It is led by the leaders of the organization, usually, the owner of the key process.

The BEST-method is an approach that explains how to assess and write a best practice. The BEST-method is also a valuable tool to assess your good practice. The outcome of this assessment will help you confirm that you have a good practice and identify where you can make further improvements to achieve a best practice.

The BEST-tool is a series of checklists (Excel-tables) enabling the reader to assess his best practice or as a guideline for writing a best practice. There are two tools: the detailed BEST-tool (a detailed checklist consisting of four elements (4 Excel tables)) and the BEST Quick Scan (a summary of the BEST-tool in one checklist (1 Excel table)).

Short Presentation Of BEST-Method

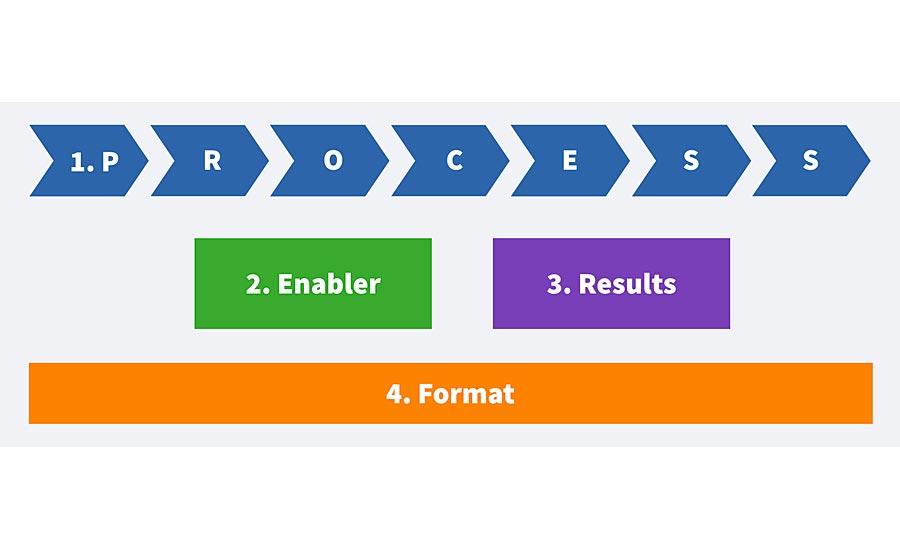

The BEST-method consists of four building blocks (see figure 1): process description, enablers (methods used), results achieved and the description of the best practice (format).

Figure 1: Four building blocks of the best-method.

*Click the image for greater detail

1. It starts with the identification and description of the key process. This process contributes positively to the achievement of the strategic goals and/or business plan. In many cases it is described in the format of a flowchart. The management of the key process consists of three parts: 1) description of the enablers (approaches and methods) used to implement and improve the process (enablers), 2) monitoring of the results and 3) the description of the Best Practice (format).

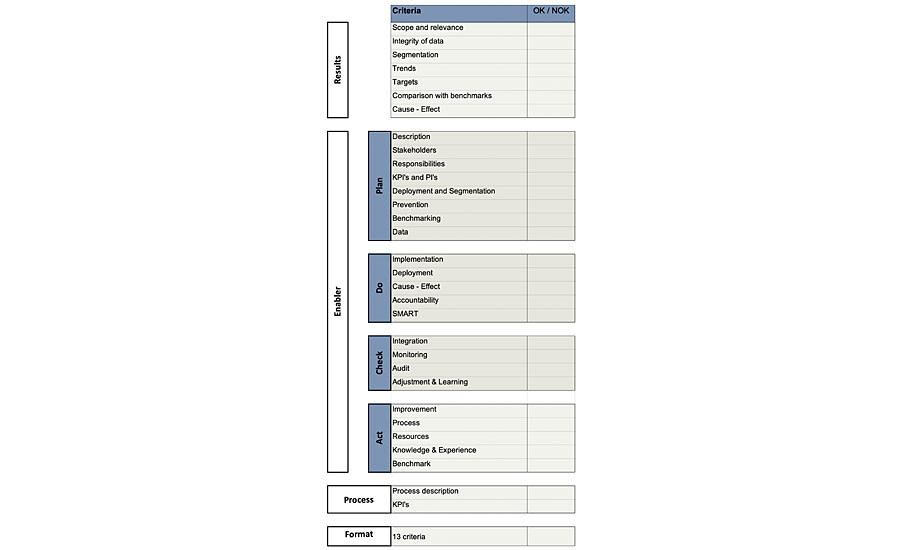

Table 1: Overview of the detailed Best-tool

*Click the image for greater detail

The enabler is assessed according the PDCA-logic, i.e., Plan, Do, Check and Act cycle. Each of these four phases consists of several criteria. There are two types of assessments: Quick Scan BEST-method and detailed BEST-method. The Quick Scan is limited to the level of criteria, while in the detailed BEST-method each criterion is subdivided into several characteristics.

Table 2 gives an overview of the four elements of the Quick Scan BEST-method, i.e., results, enabler, process description and format of the Best Practice description. You cannot cherry pick. You must assess all four elements and their criteria together.

The advantage of the Quick Scan BEST-method, as the word explains itself, is that it is quick. You will be able to do the assessment in less than half an hour.

Table 2: Quick scan Best-method (checklist)

*Click the image for greater detail

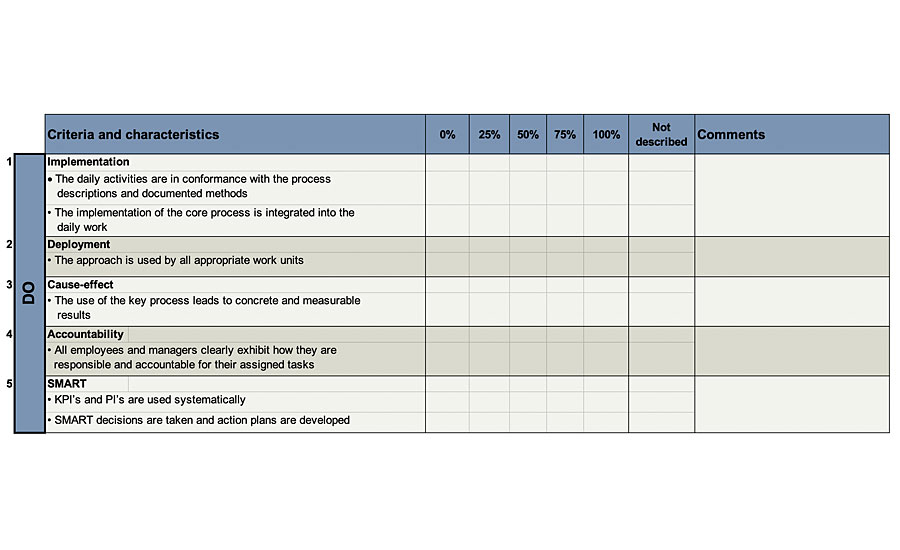

Once this test has confirmed that you probably have a best practice, you can assess the best practice with the Detailed BEST-method. In this case the criteria are subdivided into several characteristics. Table 3 is an example of one of the enabler elements, i.e. Do-phase.

Table 3: Criteria for the evaluation of the approaches (enablers of a best practice process

*Click the image for greater detail

The output of the assessment is a list of strengths and areas for improvement. From this end report the assessor can immediately see gaps in the management of the key process that need further improvement before it can be recognized as a best practice.

Preconditions

Before you can start with an assessment of a best practice, the following conditions must be met: the key process is defined, the results linked to this key process are available and there is a detailed text of the description of the best practice. As soon you have confirmed that these conditions are fulfilled, you can start with the assessment of the best practice using the BEST-tool.

The BEST-tools (BEST Quick Scan and BEST Detailed Scan) are available for free download online. These are Excel tables which can be used immediately.

Sometimes there is confusion between the word “audit” and “assessment.” Table 4 a compares these two concepts.

There are, of course, several similarities between these two concepts, such as top management commitment, process orientation, results orientation, customer orientation, continuous improvement, evidence-based management, prevention, etc. The emphasis of the BEST-method is to assess a process and evaluate opportunities for improvement leading to an excellent best practice.

Advantages

There are several advantages in using the BEST-method.

- You have a handy tool to assess both a good practice and a best practice.

- The tool provides the means to evaluate, and thus improve, key processes independently from a full QMS perspective.

- You will know when the level of best practice is reached and how others can study your process as a real benchmark.

- Applying the BEST-tool contributes another step in your journey to excellence.

- You will discover opportunities for improvement in your approach (enabler).

- The application of the BEST-tool reveals how your process results could be improved.

- You will better understand the segmentation of process results.

- You gain a higher level of collaborator involvement through discussing the description and assessment of your best practice.

- You give the collaborators a reason to be proud of their achievements.

- The best practice can be used as training material within your organization.

- The best practice process provides a structured approach to new employee orientation.

- In a multinational company, the best practice can be used as an internal benchmark. It allows colleagues from other plants and divisions to learn from each other.

- The BEST-method allows you to check the effectiveness and efficiency of your key process.

Conclusion

It is now possible to assess a best practice in a systematic way. The output of this assessment confirms that you indeed have a true best practice or that you need to develop an action plan for further improvement based on the gaps identified by the BEST-tools.

Acknowledgement: We thank Cary Black (CK Black Group) and Ed Nodland (Jet Stream Innovations) for their feedback in illustrating the value of the BEST-method.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!