Better Machine Vision: The Benefits of Combining 2D and 3D

Part 1

In the world of automated industrial quality control and inline inspection, both 2D and 3D technology have important roles to play. In this three part blog series we will look at the strengths and limitations of each, and how combining the two creates a more complete inspection system.

Starting with 2D Technology

2D is the more established of the two technologies, and over the past 30 years has proven highly effective in a wide range of automation and product quality control processes.

Contrast Driven Feature Processing

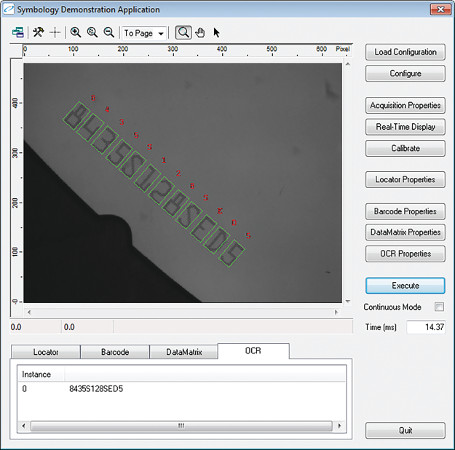

2D technology delivers results based on features relating to contrast in a grayscale or color image. 2D is suited to applications for absence/presence detection, discrete object analysis, pattern alignment, barcode and optical character recognition (OCR), and a variety of 2D geometric analysis based on edge detection for fitting lines, arcs, circles and their relationships (distances, angles, intersections, etc).

Pattern Matching: A Key To Handling Part Variation

2D technology is largely driven by contour-based pattern matching to identify part location, scale and orientation. Technicians can use 2D to identify a part and create inspection tools that dynamically adapt to the part’s position, angle, and size for robust measurement due to part movement. Today’s pattern matching handles occlusions, clutter, distortion, contrast reversal, overlapping parts, and uneven lighting.

2D MACHINE VISION IS USED FOR:

- Barcode and character reading

- Label inspection and verification

- Basic positional verification

- Feature presence and 2D dimensional verification

- Surface marking detection

Limitations of 2D Technology

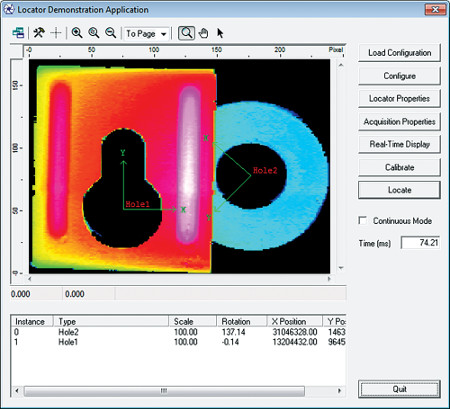

Can’t Measure Shape

2D sensors don’t support measurement related to shape. For example, 2D sensors aren’t able to measure features such as object flatness, surface angles, part volumes, or differentiate between objects of the same color, or differentiate between object positions with touching sides.

Vulnerable to Variable Lighting Conditions

Because lighting determines edge locations and measurement accuracy, lighting variations across the sensor’s field-of-view can sometimes cause edge measurement errors unless specific techniques are used to compensate for this effect. In factory conditions, lighting variation is a common challenge from unexpected ambient or spot sources on the manufacturing floor.

Limited Contrast Compensation

2D sensors rely on measuring an object’s contrast (edge data), which, for example, means they are unable to measure a black object on a black background or distinguish part features without specific lighting to expose the presence and definition of an edge.

Sensitive to Object Movement

Because of errors caused by component movement, 2D sensors require precise fixturing along the optical axis (Z axis), the use of scale-invariant feature detection, or large telecentric optics (must match size of FOV) to remove the effect.

Stay tuned for Part 2 on 3D technology