Software

Software

Recognize a Payback for Collecting Test and Metrology Data

There are three key actions necessary to gain value from collecting and analyzing quality data.

March 27, 2025

Software

Data Diversity: A Connected Approach to Quality

It’s time to unlock the potential of metrology data.

March 17, 2025

Manufacturing Software

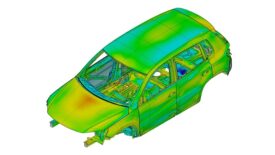

New Software Assesses, Validates Stamping Processes

Simulation software lets engineers evaluate and fine-tune stamping lines before dies are cut or parts are produced.

March 12, 2025

Software

AI in Manufacturing: Reshaping Quality Control and Efficiency

AI is profoundly reshaping manufacturing, enabling businesses to achieve higher quality standards, greater operational efficiency and more imaginative resource utilization.

February 26, 2025

Software

ERPs Remain Highly Beneficial, but Success Depends on the Right Plan and Approach

The key to ERP success is starting off on the right foot.

February 25, 2025

Software

How Generative AI Could Revolutionize Manufacturing Quality Functions

True quality starts with avoidance of mistakes and bad data

February 24, 2025

Quality Rocks

The Rise of Quality Escapes (and What to Do About it)

How quality affects every part of our lives – including breakfast.

February 16, 2025

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing