Test & Inspection

Test & Inspection

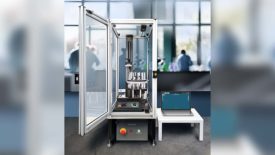

A universal tester can regularly be found implementing tension and compression applications in QC and R&D environments.

Read More

Aerospace Manufacturing

Smart Robot Automates Inspection of Helicopter Blades

New technology is more accurate and less labor-intensive than manual inspection.

April 2, 2024

Test & Inspection

How to Improve Quality Control by Managing a Drifting Zero Point during Air Leak Testing

Why zero drift occurs and ways to mitigate or even eliminate it.

March 25, 2024

Test & Inspection

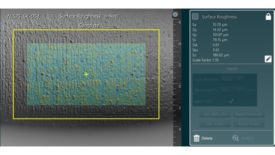

The Importance of Digital Surface Inspection in Additive Manufacturing

As 3D printing continues to take off and parts are used in more unique ways to solve complex problems, it’s likely that quality requirements will only become stricter.

March 1, 2024

Test & Inspection

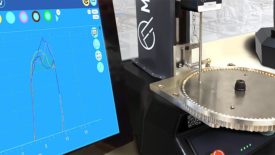

The Accuracy Nexus: 3D Scanning in Additive Manufacturing for Custom Car Builds and Mesh Repair Solutions

Anyone can buy a 3D printer and set up a shop, but there are a few essential things to know — especially when it comes to mesh repair.

February 23, 2024

Test & Inspection

Navigating the Nuances of Additive Manufacturing Quality Control

The evolution from traditional methods to additive manufacturing represents a paradigm shift.

February 16, 2024

Test & Inspection

Crushing it: a granular breakdown of testing what shouldn’t break down

While tensile testing garners significant attention, compression testing is equally crucial.

January 26, 2024

Test & Inspection

When Part Gaging is a Bottleneck

Automatic manual gauging improves process control, yield, and capacity.

January 26, 2024

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing